Which is the best, Electric Drive or Fluid Drive?

Key words:Is it possible to produce a precise hydrauric control system without any control valves.

1. Preface

Recently we have many occasions to see the papers of “Which is the best, Electric Drive or Fluid Drive?” for actuators. Most papers extend their theses based on writers’ favor for either electric drive or fluid drive.

Each actuator of the two types of drives has its merits and demerits and it is not so easy to determine which one is superior to the other.

|

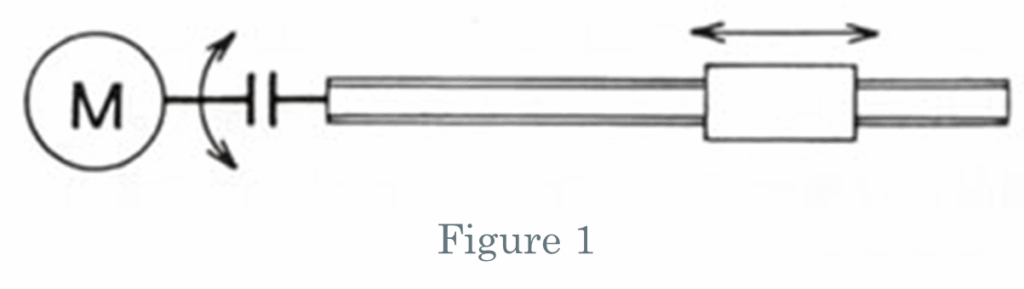

Figure 1 |

We have developed an actuator with totally new ideas to solve these disputes. Details of the actuator are elaborated on as below:

2. Definitions of Electric Drive and Fluid Drive

We define these two drives as follows:

It is reasonable and acceptable to most people that the drive, in which an electric motor rotates to both directions and drives a threaded bar so that a nut on the bar moves in line with the threaded bar, is called Electric Drive Actuator. Of course, the drive in which the rotation of crank shaft is converted to the linear movement or the drive which combines ball screw and toggle mechanism can be also called Electric Drive. To sum up, the drive, in which the rotating direction, rotating speed and torque of electric motor are controlled and transmitted to ball screw and produces the linear movement of nut, should be defined as Electric Drive Actuator.

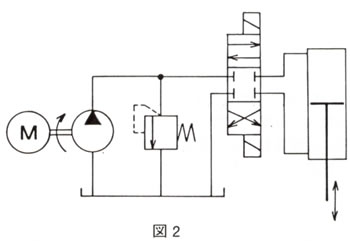

Fluid Drive is normally defined as the mechanism as shown Illustration 2, in which an electric motor drives an oil pump to produce oil pressure which is converted to the linear movement of cylinder rod through direction control valves. In other words, Fluid Drive is defined as the mechanism in which electric motor and oil pump produce a certain level of oil pressure and control valves (direction control valves, oil flow control valves and pressure control valves or servo valves) control the direction of cylinder rod, speed and thrust by regulating the pressurized oil.

Rotating mechanism by fluid oil is also included in Fluid Drive. By the same token, the mechanism, in which an electric motor rotates to one direction at a constant speed and an oil pump produces a certain amount of pressurized oil, then valves open and shut the flow, controls the direction of oil flow to move the cylinder rod, can also be defined as Fluid Drive.

Therefore, the mechanism, in which ball screw and nut are used just as media to transfer the rotating force of electric motor that has control functions, can be called Electric Drive.

3.Actuator of Ambiguous Definition

The actuator we developed has an electric motor which is connected to a bi-directional pump as shown blow and controls the oil discharge directions, oil flow rate and oil pressure by the rotating directions, rotating speed and torque of the motor. The oil cylinder is actuated by the pressurized oil.

This idea was revealed in the article of “Fluid Control Mechanism without the Use of Servo-valves” on Nekkei Mechanical September 19, 1994 issue. 15 years have passed since then. During this period, the agreement at Kyoto Conference of the Parties to the United Nations Framework Convention on Climate Change in 1997 imposed Japan a target of CO2 deduction which required more than 10% of energy cut from what was then used in Japan.

In this regard, the argument occurred as to which is more efficient, Electric Drive or Hydraulic Drive?

|

Figure 3 |

Looking into various literatures, the idea shown in Illustration 3 existed even in the beginning of Showa Era and HST (Hydro Static Transmission) system based on this idea was developed. But because there was no technology to change the rotating direction of motors quickly and large servo motors were extremely expensive at the moment, this system was not successfully commercialized nor did come into use.

Our actuator is developed exactly in line with this idea. But as saying that “the simpler the design, the more difficult to materialize”, it took many years to establish the reliable control technology due to so simple structure of the actuator.

Taking a close look at this system, it is easy to understand that fluid oil is just a media to transmit the rotating force of electric motor to the cylinder. Therefore, it can be said that in electric drive actuator shown in Illustration 1 ball screw (solid body) is the media to transmit force and that in fluid drive actuator in Illustration 3 fluid (liquid) is the media to transmit force. So both types can be categorized as Electric Drive Actuators.

Once our actuator is categorized as Electric Drive, it is expected that energy efficiency is equal to the one of the conventional electric drive unit. We found from our laboratory tests, however, that energy efficiency of our actuator was unbelievably better than that of the conventional ones. The energy efficiency of our actuator reached about 90%. That results in much less temperature increase of fluid oil which makes it possible to remove oil cooking unit even for long continuous operation. On top of it, vibration and noise are substantially reduced. It is as quiet as electric drive unit.

The oil circuit becomes very simple because no control valves are required. This enables us to combine an electric motor, an oil pump and a cylinder into one piece construction.

We named this actuator as Hybrid Actuator and the control method which regulates actuator directly by motor and oil pump without using any control valves are now being called DDV or DDVC (Direct Drive Volume Control).

According to the description stated above, DDVC seems to be categorized as Electric Drive. But we rather believe that DDVC is actually a mixture of merits of Fluid Drive and Electric Drive because it drives the actuator directly as an electric drive does but at the same time it incorporates fluid drives characteristics into its mechanism.

Summing up,

It inherits the merits of Electric Drive such as:

- High energy efficiency

- Easy installation like electric motor installation

- Low vibration and low noise

It is also free from various demerits of Electric Drive such as:

- Difficulty to manufacture a unit with large force

- Wear and tear occurs, and fine particles from wear prevent the use in clean rooms

From these points of view, although we called this unit ambiguous at the start of this statement, we may be able to define it as the unit of combination of control by electric drive and force by fluid drive.

We now believe and proudly propose that this Hybrid type of actuator, which embraces the merits of both electric drive and fluid drive, can conclude the argument as to the superiority of electric and fluid drive actuators.