◆ Vol.18.Comparison of HySerpack and Servo-valves (2)

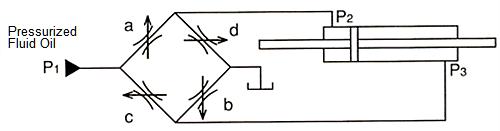

Thy typical servo-valve is normally in the shape of a 4 port spool valve. The spool position can be adjusted from close to full open continuously and without steps. So you may regard it as that the opening of each port is controlled by analog signal. Therefore it is convenient to think that the basic structure of servo-valve is identical to the diagram below which shows that 4 valves are placed and connected on a square shape.

Suppose that when servo-valve is half open, then all 4 valves in the diagram are also half open. Under this condition, the pressure of cylinder port P2 and P3 are: P2=P1/2, P3=P1/2; as a result P2 is equal to P3. So the pressures at P2 and P3 are both P1/2 and equal. Therefore, the pressures at P2 and P2 are balanced and the rod does not move.

From this balanced condition, if the valves a and b are slightly opened and valves c and d are slight closed, the pressure at P2 becomes higher than that P1/2 and the pressure at P3 becomes slightly lower than P1/2. The balance is lost and the rod moves towards the right on the diagram.

As stated above, fluid oil is incessantly pumped from oil source to valves to oil reservoir even when cylinder rod does not move at all because all valves are half open. In this kind of system both fluid oil pressure and fluid oil quantity have to be twice or three times as much as those required just for controlling cylinder movement.

HySerpack has got rid of this kind of orifice control method so it only requires the oil pressure and the oil quantity which is just sufficient to control the cylinder. This results in the power consumption of HySerpack only one-forth to one-ninth as little as that of the conventional fluid systems with servo-valves.