◆ Vol.19 Comparison of HySerpack and Servo-valve (3)

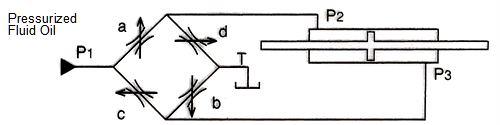

The previous section elaborates on the fact that servo-valves are equivalent to the four valves which are aligned and connected as shown below. We can regard the setting in which all four valves are half open is identical to the neutral position of servo-valves.

In this setting, the oil pressure at P2 and P3 is one half of the pressure at P1. Suppose P1=10MPa, then the pressure at P2 and P3 is 10MPa. When the pressure at both at P2 and P3 is the same, the forces produced by oil pressure are balanced so the cylinder is just stalled and doing nothing.

Thus even while cylinder rod stays still, the both cylinder chambers are still pressurized at 10MPa. In order to produce twice as much pressure as this pressure, drive motor, oil pump, and other mechanism have to keep working. All the energy consumed to keep running the driving units is not used for any job but just increases the temperature of fluid oil. Without cooking oil, it loses viscosity quickly and causes the oil leakage in pump, which further increases oil temperature. The violent increase of oil temperature may cause the decomposition and carbonization of fluid oil, which can only be avoided by forced oil cooling that claims an extra energy to do. Summing up, servo-valve control system is so ineffective that it converts most energy to heat and requires oil cooling system which consumes further energy to run.

To the contrary, on HySerpack all energy produced by drive motor and pump is used to actuate the rod. For example, when the pressure at P1 is 20MPa, the pressure at P2 is also 20MPa but P3 is zero. So whole pressure is converted to power and used to activate the cylinder. In other words, the heat generation drastically as much as the energy efficiency improves. No wasteful heat generation can make it possible to get rid of oil cooling system and any power supply to it.